Embroidery Tension Chart

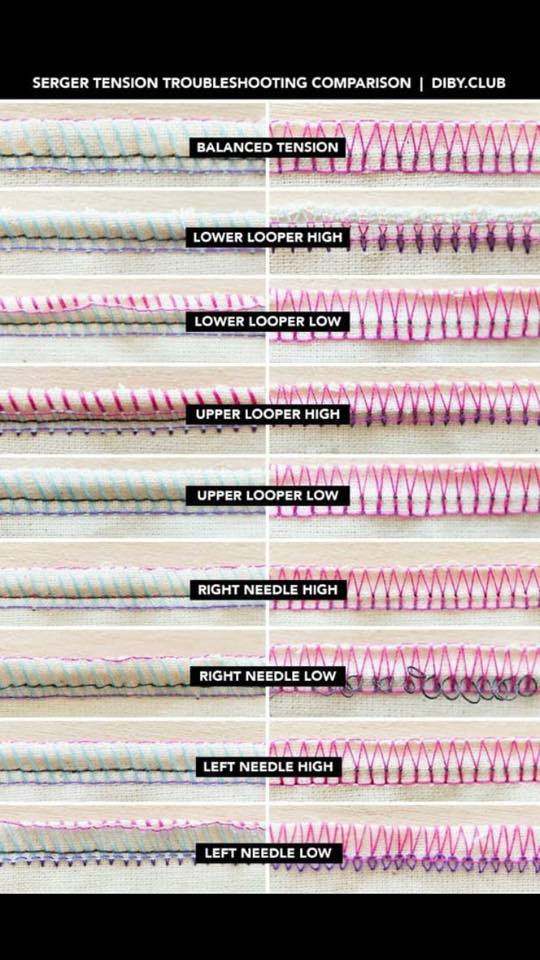

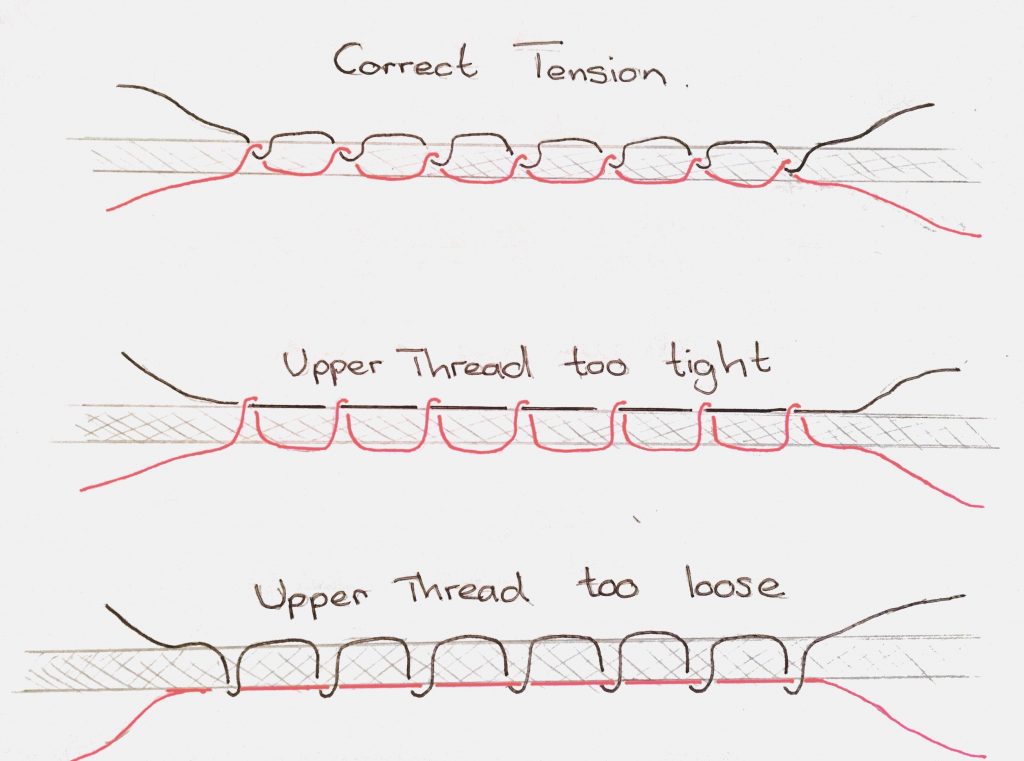

Embroidery Tension Chart - Madeira usa works with authorized distributors to make our embroidery thread and embroidery supplies even more readily available. Let’s start by first taking a look at this embroidery tension chart to determine if it is really tension that we need to know or learn more about! If the stitches appear loose, turn the tension up one notch and embroider again. Cotton thread, the top tension will most likely need to be adjusted (loosened) to accommodate an even stitch. Web your tensions will vary within each type so as you change types even within the category; Adjusting the upper thread tension. Most thread breaks are due to poor tensioning. Web knowledge at your fingertips browse our guides and charts. We will also discuss other factors that may impact tension settings and talk about ideal tension settings for various threads and fabrics. If the top thread is a thick, 30 wt. They will help you troubleshoot problems when stitching, learn more about tension and when you should tighten or loosen tension, provide information regarding bobbin compatibility and. Are you on the right road to solving your problem? Rayon thread has been the most popular thread used within the embroidery industry, but polyester is quickly becoming the thread of. Use the images to the left as a guide to achieving and maintaining proper tension. Web the tension of the upper thread can be adjusted for embroidering of the embroidery settings screen. First off, what does proper tension look like? This feather soft thread runs like rayon. The thread tension controls how tight or loose the upper and bobbin threads are pulled together. Web proper thread tensioning is essential to achieving trouble free, quality embroidery. Read on to discover how to keep your thread tension in perfect balance! If the top thread is a thick, 30 wt. This feather soft thread runs like rayon. To test the tension, create a sample embroidery on a scrap piece of fabric and check for puckering or looseness in the stitches. Let’s explore the primary types of tension systems in embroidery machines. Read on to discover how to keep your thread tension. They will help you troubleshoot problems when stitching, learn more about tension and when you should tighten or loosen tension, provide information regarding bobbin compatibility and. Madeira usa works with authorized distributors to make our embroidery thread and embroidery supplies even more readily available. First off, what does proper tension look like? Most thread breaks are due to poor tensioning.. Looping of the top thread or bobbin thread showing on top of your design are other indications of improper tensioning. Proper tension is important for good stitch quality. If the stitches appear loose, turn the tension up one notch and embroider again. Cotton thread, the top tension will most likely need to be adjusted (loosened) to accommodate an even stitch.. Web knowledge at your fingertips browse our guides and charts. If the top thread is a thick, 30 wt. First off, what does proper tension look like? The selected setting will be applied to all patterns. When embroidering, the thread tension should be set so that the upper thread. Itʼs fast and simple and will help you eliminate unsightly bobbin thread showing on top, looping top stitches and thread breaks. Cotton thread, the top tension will most likely need to be adjusted (loosened) to accommodate an even stitch. The thread tension controls how tight or loose the upper and bobbin threads are pulled together. If the top thread is. First off, what does proper tension look like? If the top thread is a thick, 30 wt. Proper tensions for satin stitches should reveal 1/3 bobbin and 2/3 top thread color on the underside of the embroidery as seen on the image above. Web madeira usa locations madeira usa has 10 conveniently placed embroidery supply locations across the united states. Web embroidery machines employ various tension systems to regulate the delicate balance between the top and bottom threads. If the top thread is a thick, 30 wt. Looping of the top thread or bobbin thread showing on top of your design are other indications of improper tensioning. Proper tensions for satin stitches should reveal 1/3 bobbin and 2/3 top thread. Web bobbin tensions should be 18 to 22 grams (up to 25 grams when embroidering caps). Web in this article we explain how thread tension can effect the final result of your machine embroidery. Web this guide provides an overview of different types of embroidery machines and how to adjust their respective tensions. When your tensions are correct, you will. Web when doing machine embroidery, the tension dial should be set somewhere between 2 to 6. Web embroidery machines employ various tension systems to regulate the delicate balance between the top and bottom threads. Web embroidery machine tension needs adjusting from time to time. To test the tension, create a sample embroidery on a scrap piece of fabric and check. Proper tension is important for good stitch quality. (1) loosen (decrease the number) (2) tighten (increase the number) (3) thread tension dial. Web this guide provides an overview of different types of embroidery machines and how to adjust their respective tensions. To adjust embroidery tension, first consider the type of thread and fabric being used. Web how thread tension issues. To test the tension, create a sample embroidery on a scrap piece of fabric and check for puckering or looseness in the stitches. Web when doing machine embroidery, the tension dial should be set somewhere between 2 to 6. Cotton thread, the top tension will most likely need to be adjusted (loosened) to accommodate an even stitch. Web embroidery machine tension needs adjusting from time to time. Use the images to the left as a guide to achieving and maintaining proper tension. First off, what does proper tension look like? Rayon thread has been the most popular thread used within the embroidery industry, but polyester is quickly becoming the thread of. When embroidering, the thread tension should be set so that the upper thread. When your tensions are correct, you will see three fairly evenly divided sections on the back of your lettering or embroidery in each segment. Web embroidery machines employ various tension systems to regulate the delicate balance between the top and bottom threads. Web bobbin tensions should be 18 to 22 grams (up to 25 grams when embroidering caps). Proper tension is important for good stitch quality. Web when tension is off, you might see clumps of thread on the underside of the fabric, bobbin thread showing on the front of the design, looping threads, or thread breaks. Shop premium embroidery threads by type. Adjusting the upper thread tension. When embroidering, if the overall tension of the upper thread is too tight or too loose, adjust it.Embroidery Tension Chart for Beginners

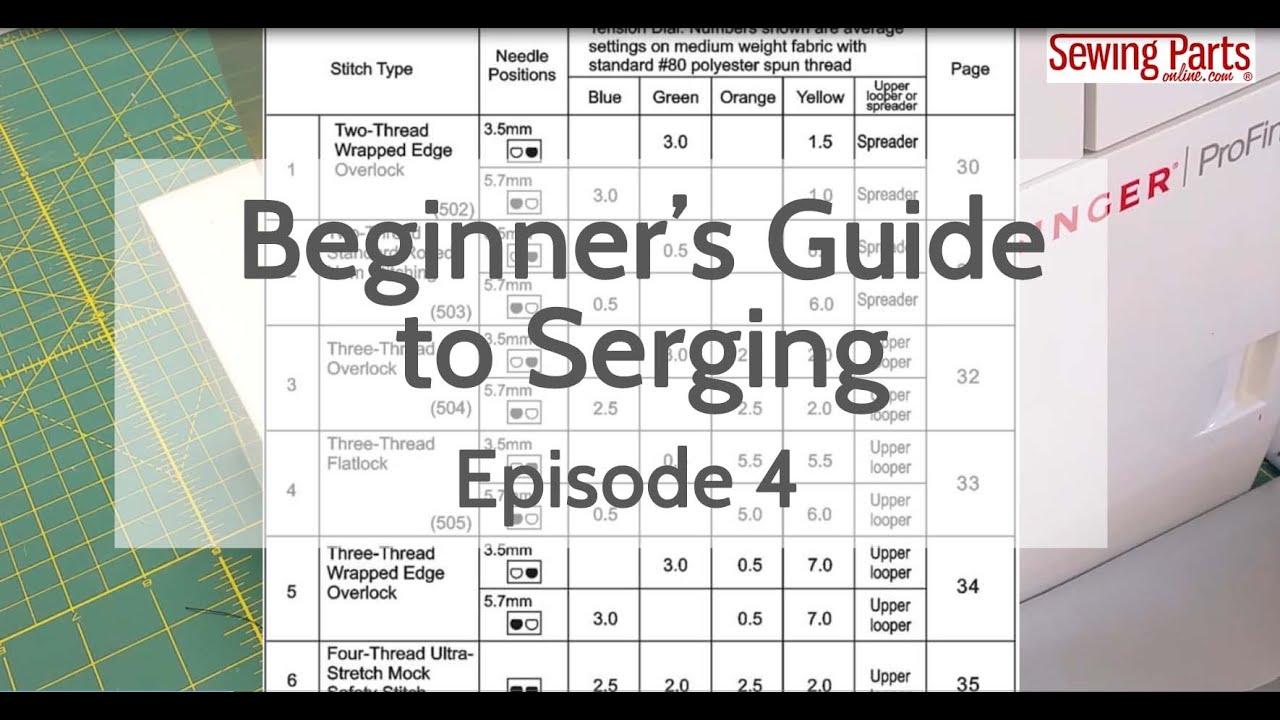

Beginner's Guide to Serging (Ep 4) Overlock Stitch + Intro to Tension

Embroidery Thread Tension Guide

embroidery tension

Embroidery Machine Tension Guide

Thread Tension On Embroidery Machine

Machine embroidery stabilizer guide free printable chart Artofit

Stitch Length Best, Standard & How to Adjust TREASURIE

Embroidery Machine Top Thread Tension Chart

Embroidery Machine Tension Guide

Classic Rayon The Original Embroidery Thread, Unmatched In Color, Luster And Satiny Soft.

You Must Check Your Tension.

Web Knowledge At Your Fingertips Browse Our Guides And Charts.

Web It Is Important To Keep A Total Balance Between Your Upper Thread (Top Thread) And Your Lower Thread (Bobbin Thread).

Related Post: