Mig Welding Wire Size Chart

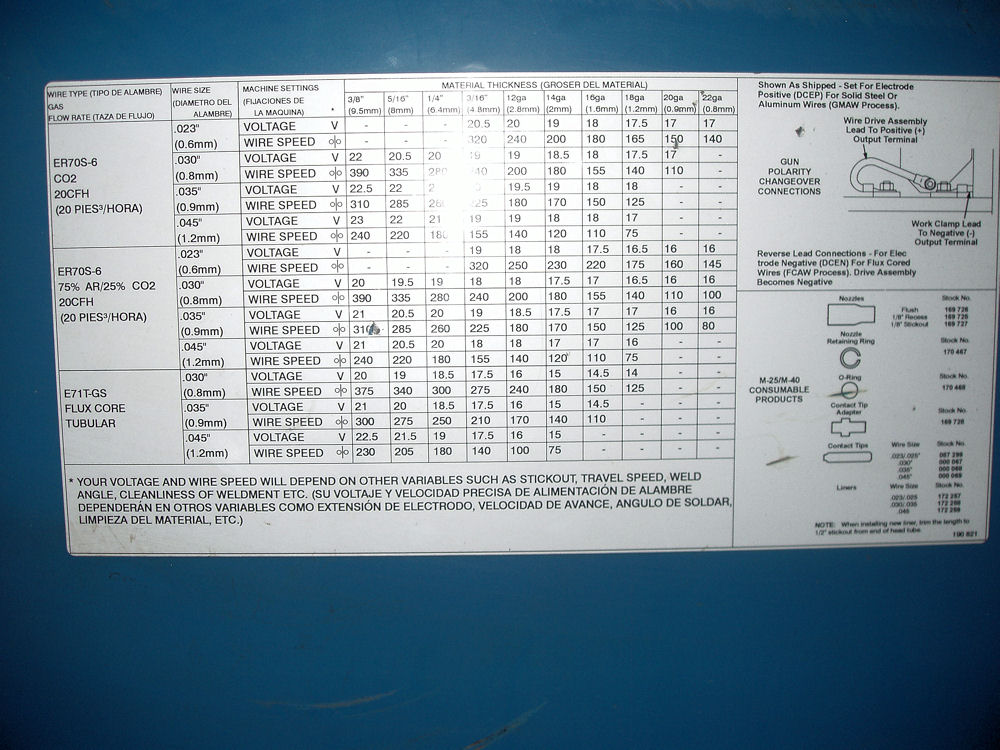

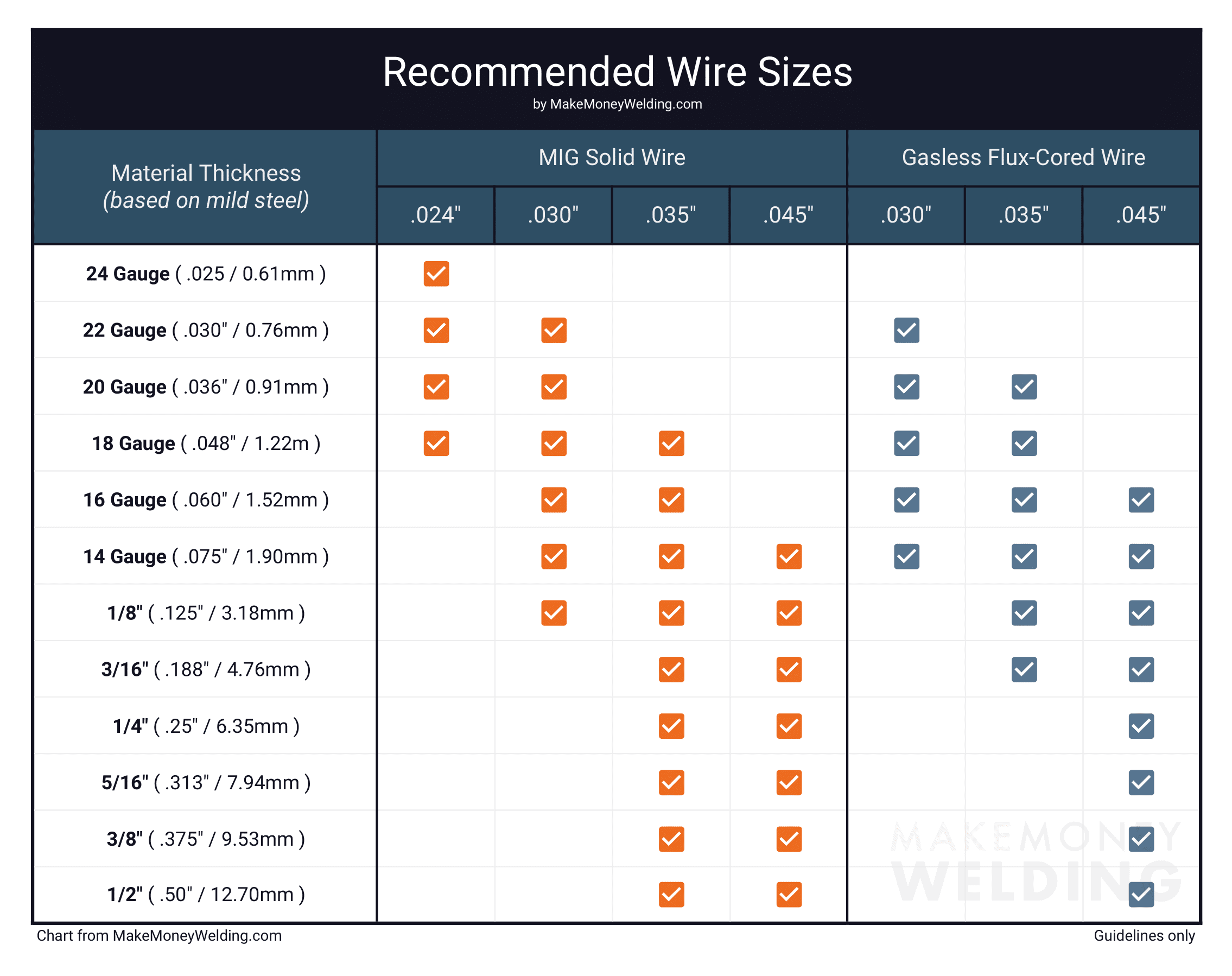

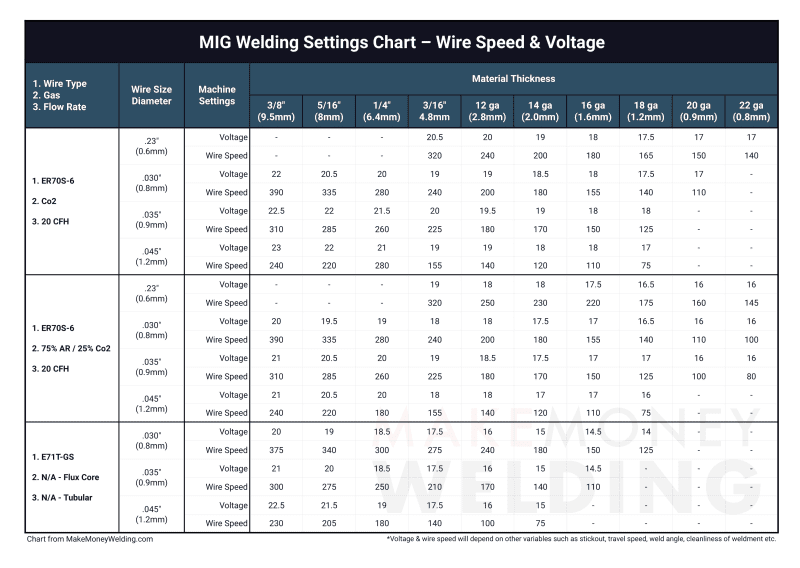

Mig Welding Wire Size Chart - Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. Notice that these sizes overlap through each current range. It's important to note that mig wire size is not the only factor that determines the strength of a weld. If you were also looking for a special wire for a mig welder, you end up at the right spot because we have a detailed guide. This gives you some choice about what works best for your welder and your technique. Web quick guide for selecting mig wire size and welder amperage for your application. Select proper wire size according to amperage. On a mig welding contact tip sizing chart, you will notice a column that says “recess/extension.” understanding this measurement is crucial for being able to pick out the right contact tip for your work, although it is often an overlooked factor. Your mig welding wire size will determine the amperage setting used. Before tackling any mig welding application, look at the charts and tips below. Numbers might be slightly off when setting up your welding machine but you will get the general fell after a few tries. Below is a full chart of recommended wire sizes based on the thickness of the welded material: This is a simple mig welding wire thickness chart with some basic and generic values for every mig welder. Web the most common mig wire sizes range from 0.023 to 0.045 inches for welding various metal thicknesses. Mig welding has different qualities and types of wires that have unique features. Web what is contact tip recess? Web mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. Web a mig wire size chart provides recommended wire diameters for different metal thicknesses. There is a widely accepted point of view that “thin” metal should be welded with “small” diameter wire. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. It's important to note that mig wire size is not the only factor that determines the strength of a weld. Web mig wire chart. Notice that these sizes overlap through each current range. What impacts mig welding wire speed? This will be good for most jobs up to about ½”. Before tackling any mig welding application, look at the charts and tips below. For thicker materials use a larger wire diameter and larger machine, check the recommended welding capability. Web for example, when welding sheet metal, the most common wire sizes are 0.35 and 0.45 inches. Web mig wire chart. This gives you some choice about what works best for. This is a simple mig welding wire thickness chart with some basic and generic values for every mig welder. Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. Use stainless steel wire for stainless steel, aluminium wires for aluminium and steel wires for steel. Web what is contact tip recess? Web esab's mig wire selection guide. What impacts mig welding wire speed? Web in this blog post, we will explore the key factors that affect mig welding sheet metal, including wire size, gas selection, amperage, and voltage. Web the most common mig wire sizes range from 0.023 to 0.045 inches for welding various metal thicknesses. Web what is contact tip recess? Web esab's mig wire selection. In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Mig welding has different qualities and types of wires that have unique features. This is a simple mig welding wire thickness chart with some basic and generic values for every mig welder. Standard sizes range from 0.023 to 0.045 inches for welding. Web a mig wire size chart provides recommended wire diameters for different metal thicknesses. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Stainless steel and aluminium amps chart. Web you choose your wire size by the amperage setting, which in turn depends on material thickness.. Web what is contact tip recess? Web you choose your wire size by the amperage setting, which in turn depends on material thickness. We will also provide tips and best practices to help you achieve optimal welding results. Stainless steel and aluminium amps chart. This will be good for most jobs up to about ½”. Web for example, when welding sheet metal, the most common wire sizes are 0.35 and 0.45 inches. Web what is contact tip recess? Web quick guide for selecting mig wire size and welder amperage for your application. Select proper wire size according to amperage. Check with your machine manufacturer for any information that may pertain to your welding system. Selecting the appropriate mig wire size is crucial for successful welding. This gives you some choice about what works best for your welder and your technique. Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. Notice that these sizes overlap through each current range. This will be. There is a widely accepted point of view that “thin” metal should be welded with “small” diameter wire. However, you will need special wire if you plan to weld other metals, such as aluminum. Web one of the many things to choose in mig welding is the size of mig wire you want to use. Check with your machine manufacturer. Use stainless steel wire for stainless steel, aluminium wires for aluminium and steel wires for steel. If you were also looking for a special wire for a mig welder, you end up at the right spot because we have a detailed guide. Web the most common mig wire sizes range from 0.023 to 0.045 inches for welding various metal thicknesses. This will be good for most jobs up to about ½”. Before tackling any mig welding application, look at the charts and tips below. Selecting the appropriate mig wire size is crucial for successful welding. This gives you some choice about what works best for your welder and your technique. Table of wire speed for mig welding. .125 inch = 125 amps. However, when welding thin steel, you’ll probably need a solid mig wire with a smaller diameter, either 0.24 or 0.30 inches. There might be variations with the settings depending on the manufacturer. Check with your machine manufacturer for any information that may pertain to your welding system. Web mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. Web what is contact tip recess? Web esab's mig wire selection guide will help you make the right choice for the types of welds you want to make and the machines in your shop. What impacts mig welding wire speed?MIG Welding Electrodes Wire Selection, Charts Settings and Classification

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Mig Welding Settings Chart

MIG + Flux Core Welding Wire Size Chart Beginner Welding Guide

MIG Flux Core Welding Wire Types Specification (with Chart), 47 OFF

Welding Cable Size Guide Charts & Tips for the Right Choice

MIG Welding Wire Essentials A Guide to Types & Uses

Welding Wire Size Chart Welding wire, Welding cable, Welding

MIG + Flux Core Welding Wire Size Chart Beginner Welding Guide

Important MIG Welder Settings You Need to Know (with Chart)

Covering Classifications, Refrence Charts And Gas Choices.

Select Proper Wire Size According To Amperage.

Web A Mig Welding Wire Speed Chart Offers Insights Into Appropriate Wire Speeds For Various Material Thicknesses And Types In Mig Welding.

On A Mig Welding Contact Tip Sizing Chart, You Will Notice A Column That Says “Recess/Extension.” Understanding This Measurement Is Crucial For Being Able To Pick Out The Right Contact Tip For Your Work, Although It Is Often An Overlooked Factor.

Related Post: