Tire Torque Chart

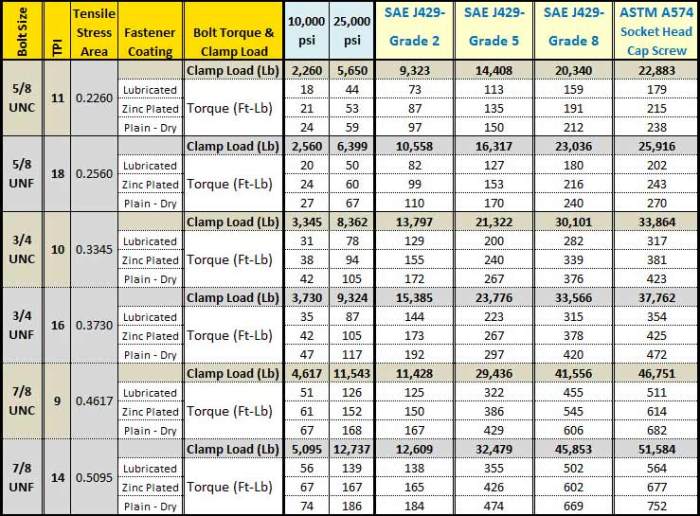

Tire Torque Chart - Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. Web it is highly important to torque your lug nuts to the correct torque to prevent warping of the wheel and even your brake rotors. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially with alloy or painted wheels. Every vehicle has its own torque requirements. Web torque the lug nuts in two steps, starting at 40 ft/lbs of torque for your first step to get the wheel seated properly. Web consult the vehicle’s owner’s manual or a lug nut torque spec chart for the correct torque values. Tighten in a star pattern to evenly distribute the load and prevent warping. A star pattern, or crisscross sequence, is crucial to ensure an even distribution of torque across the wheel. Bolts (or silver wheel bolts retroactively) escort w/aluminum wheels. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts. Every vehicle has its own torque requirements. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. And it's critical to safely installing your wheels. Web consult the vehicle’s owner’s manual or a lug nut torque spec chart for the correct torque values. Using the proper torque helps ensure that the wheel assembly is securely installed. Web a lug nut torque spec chart provides the proper torque specifications for your car’s wheels. Web finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. A star pattern, or crisscross sequence, is crucial to ensure an even distribution of torque across the wheel. Web if you are planning on installing a wheel on your vehicle, it is important to be aware of the manufacturer recommended torque settings. Web it is highly important to torque your lug nuts to the correct torque to prevent warping of the wheel and even your brake rotors. Utilizing a torque wrench is a must so you can be sure you're applying the correct torque for wheel nuts and bolts. Tighten in a star pattern to evenly distribute the load and prevent warping. Bolts (or silver wheel bolts retroactively) escort w/aluminum wheels. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially. Read on to learn more about the lug nut torque, its. Web finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. Web if you are planning on installing a wheel on your vehicle, it is important to be aware of the manufacturer recommended torque settings.. Web consult the vehicle’s owner’s manual or a lug nut torque spec chart for the correct torque values. Web it is highly important to torque your lug nuts to the correct torque to prevent warping of the wheel and even your brake rotors. Utilizing a torque wrench is a must so you can be sure you're applying the correct torque. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially with alloy or painted wheels. Using the proper torque helps ensure that the wheel assembly is securely installed. Utilizing a torque wrench is a must so you can be sure you're applying the correct torque for wheel nuts and bolts. Web consult the vehicle’s. Bolts (or silver wheel bolts retroactively) escort w/aluminum wheels. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. Web it is highly important to torque your lug nuts to the correct torque to prevent warping of the wheel and even your brake rotors. Web finding the proper torque for. Every vehicle has its own torque requirements. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially with alloy or painted wheels. Web torque the lug nuts in two steps, starting at 40 ft/lbs of torque for your first step to get the wheel seated properly. Web it is highly important to torque your. Web the graphic below shows the three common bolt patterns and tightening sequences, appropriate for most automotive applications. Using the proper torque helps ensure that the wheel assembly is securely installed. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially with alloy or painted wheels. And it's critical to safely installing your wheels.. Web a lug nut torque spec chart provides the proper torque specifications for your car’s wheels. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially with alloy or painted wheels. Web finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles. Web a lug nut torque spec chart provides the proper torque specifications for your car’s wheels. A star pattern, or crisscross sequence, is crucial to ensure an even distribution of torque across the wheel. Web torque the lug nuts in two steps, starting at 40 ft/lbs of torque for your first step to get the wheel seated properly. Then for. Every vehicle has its own torque requirements. Read on to learn more about the lug nut torque, its. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. Web consult the vehicle’s owner’s manual or a lug nut torque spec chart for the correct torque values. Web torque the lug. Web the graphic below shows the three common bolt patterns and tightening sequences, appropriate for most automotive applications. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts. Read on to learn more about the lug nut torque, its. It is prudent to recheck the torque specifications after a test drive of the vehicle, especially with alloy or painted wheels. Bolts (or silver wheel bolts retroactively) escort w/aluminum wheels. Tighten in a star pattern to evenly distribute the load and prevent warping. Utilizing a torque wrench is a must so you can be sure you're applying the correct torque for wheel nuts and bolts. Web if you are planning on installing a wheel on your vehicle, it is important to be aware of the manufacturer recommended torque settings. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. 911 targa 4, 911 targa 4s, turbo, turbo s cabrio all w/ black escort. Web finding the proper torque for lug nuts and lug bolts is the first step and can usually be found in the vehicles owner's manual. Web it is highly important to torque your lug nuts to the correct torque to prevent warping of the wheel and even your brake rotors. This involves using a torque wrench to apply the specified amount of force to each lug nut in a star or crisscross pattern. Using the proper torque helps ensure that the wheel assembly is securely installed. Every vehicle has its own torque requirements. Web torque the lug nuts in two steps, starting at 40 ft/lbs of torque for your first step to get the wheel seated properly.Ford focus wheel torque settings

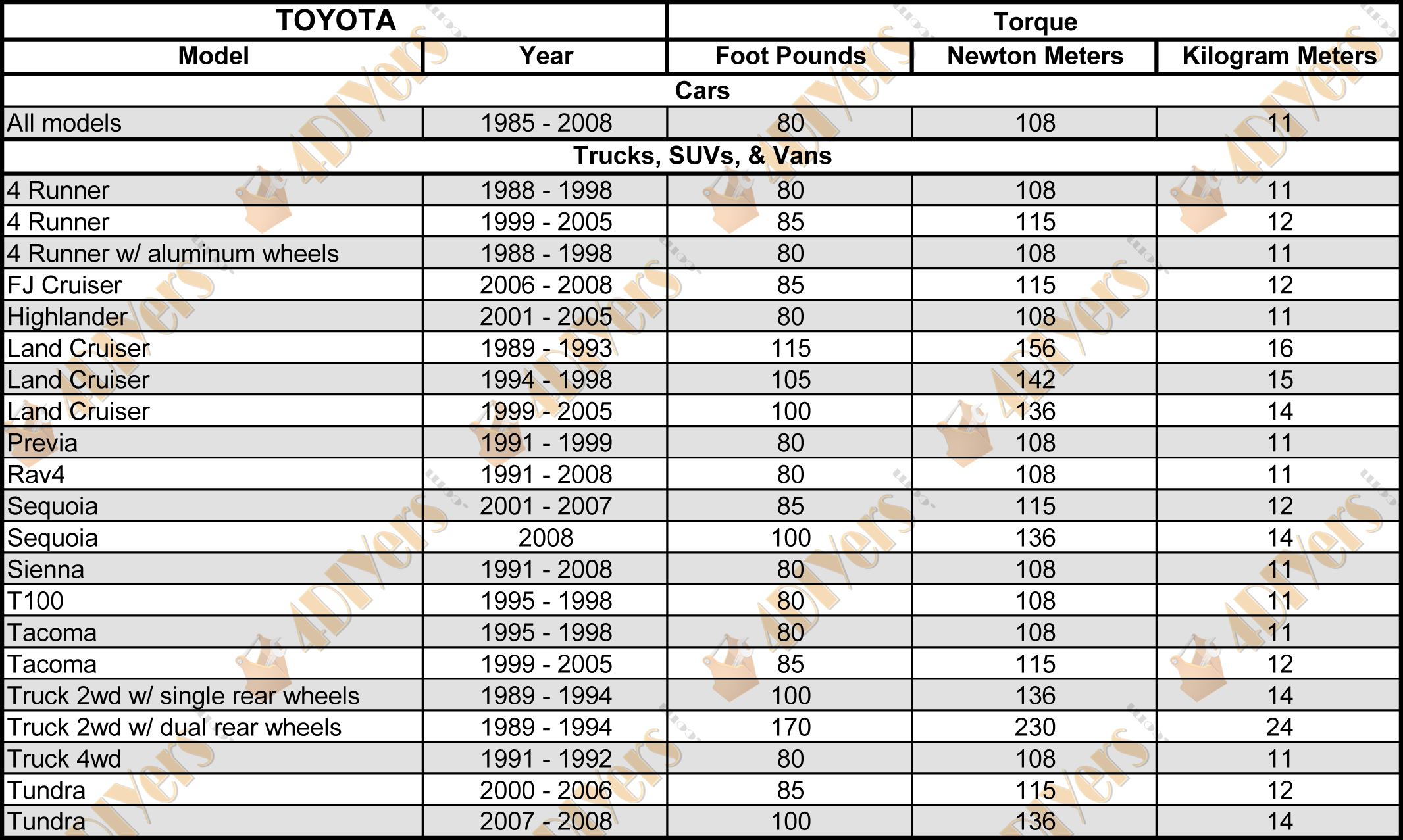

Tire Torque Spec Chart

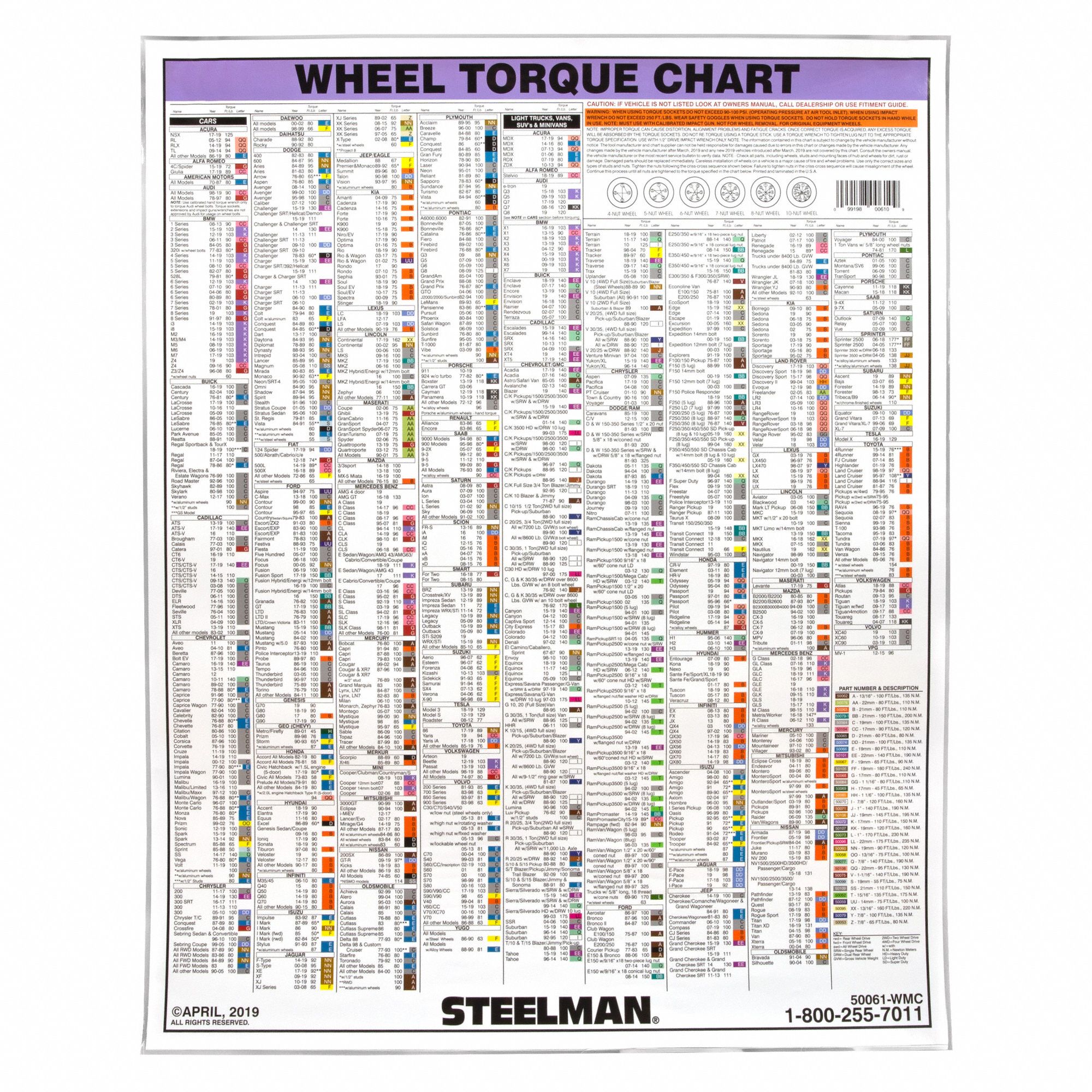

Printable Automotive Wheel Torque Chart

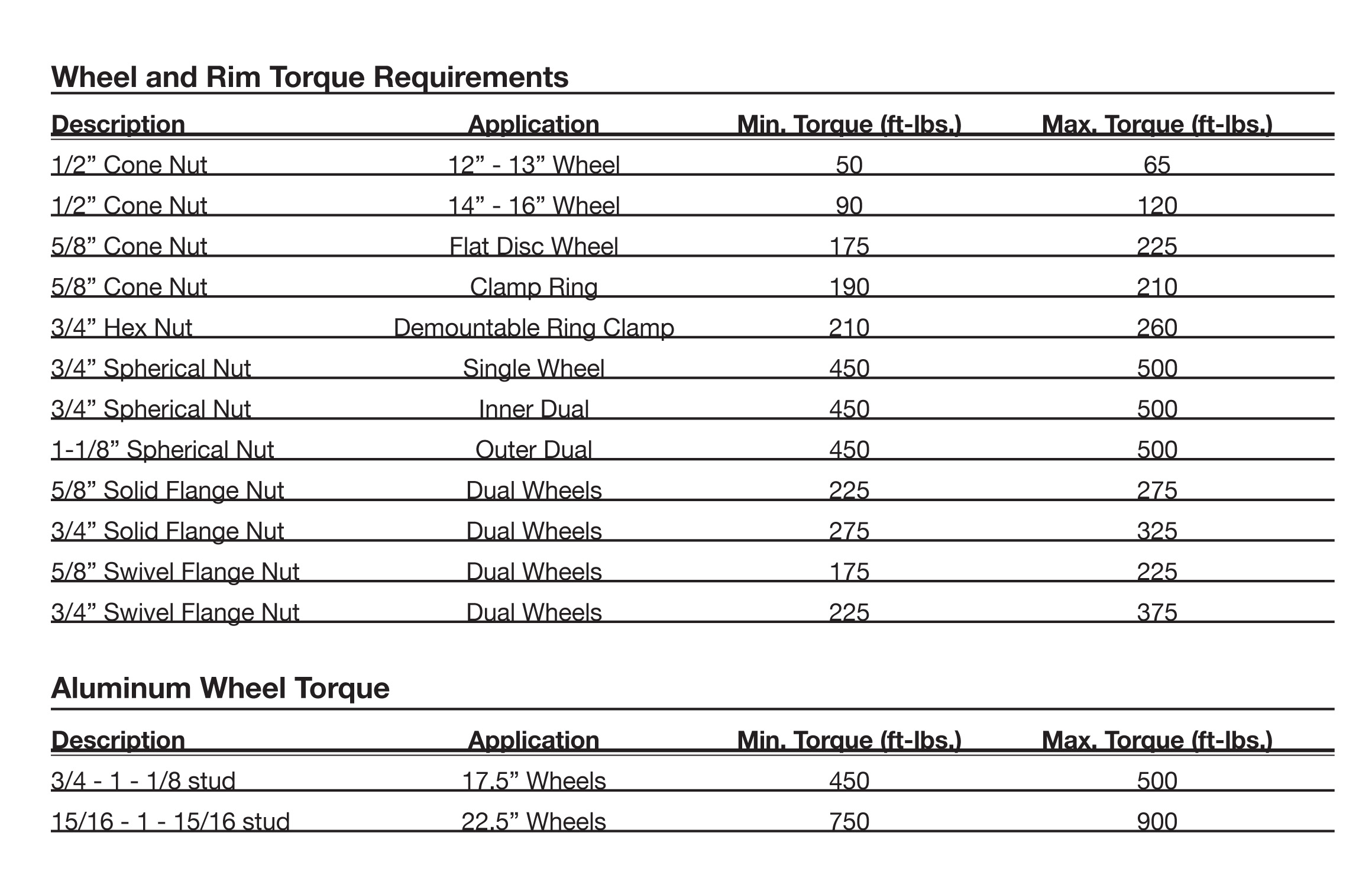

RT03 Torque Chart PDF

Lug Nut Torque Chart 2022 Version Tire Supply Network

Tire Torque Spec Chart

Tire Torque Chart

Tire Torque Spec Chart

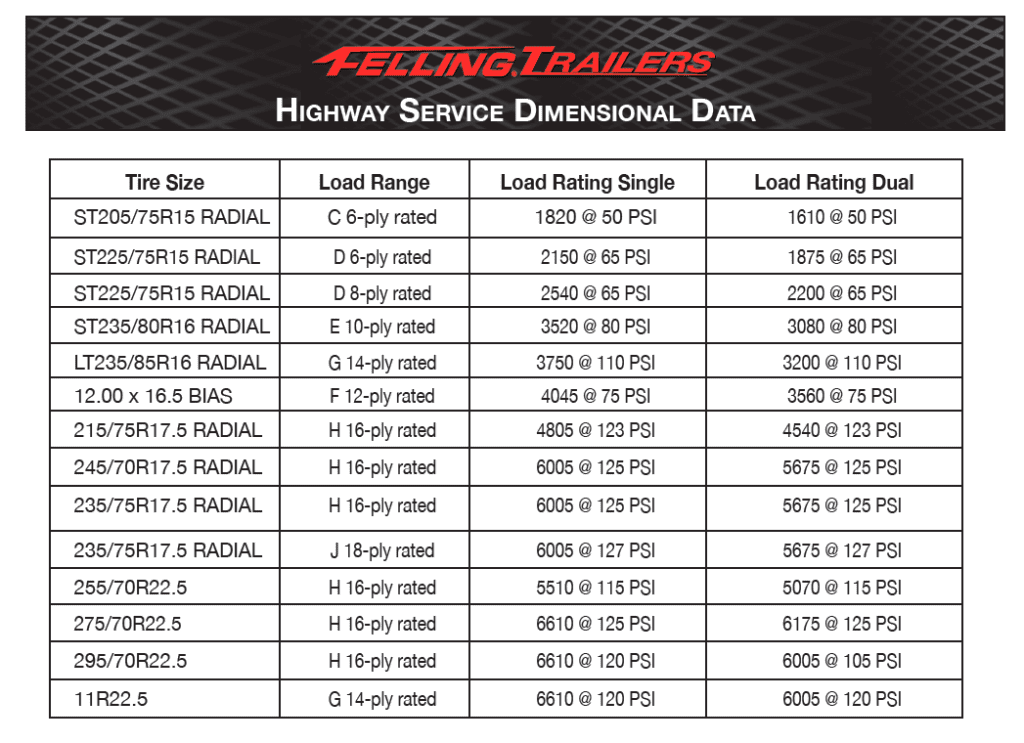

Trailer Wheel Lug Nut Torque Chart Pdf

Wheel Torque Specs Chart

And It's Critical To Safely Installing Your Wheels.

Web A Lug Nut Torque Spec Chart Provides The Proper Torque Specifications For Your Car’s Wheels.

A Star Pattern, Or Crisscross Sequence, Is Crucial To Ensure An Even Distribution Of Torque Across The Wheel.

Web Consult The Vehicle’s Owner’s Manual Or A Lug Nut Torque Spec Chart For The Correct Torque Values.

Related Post: